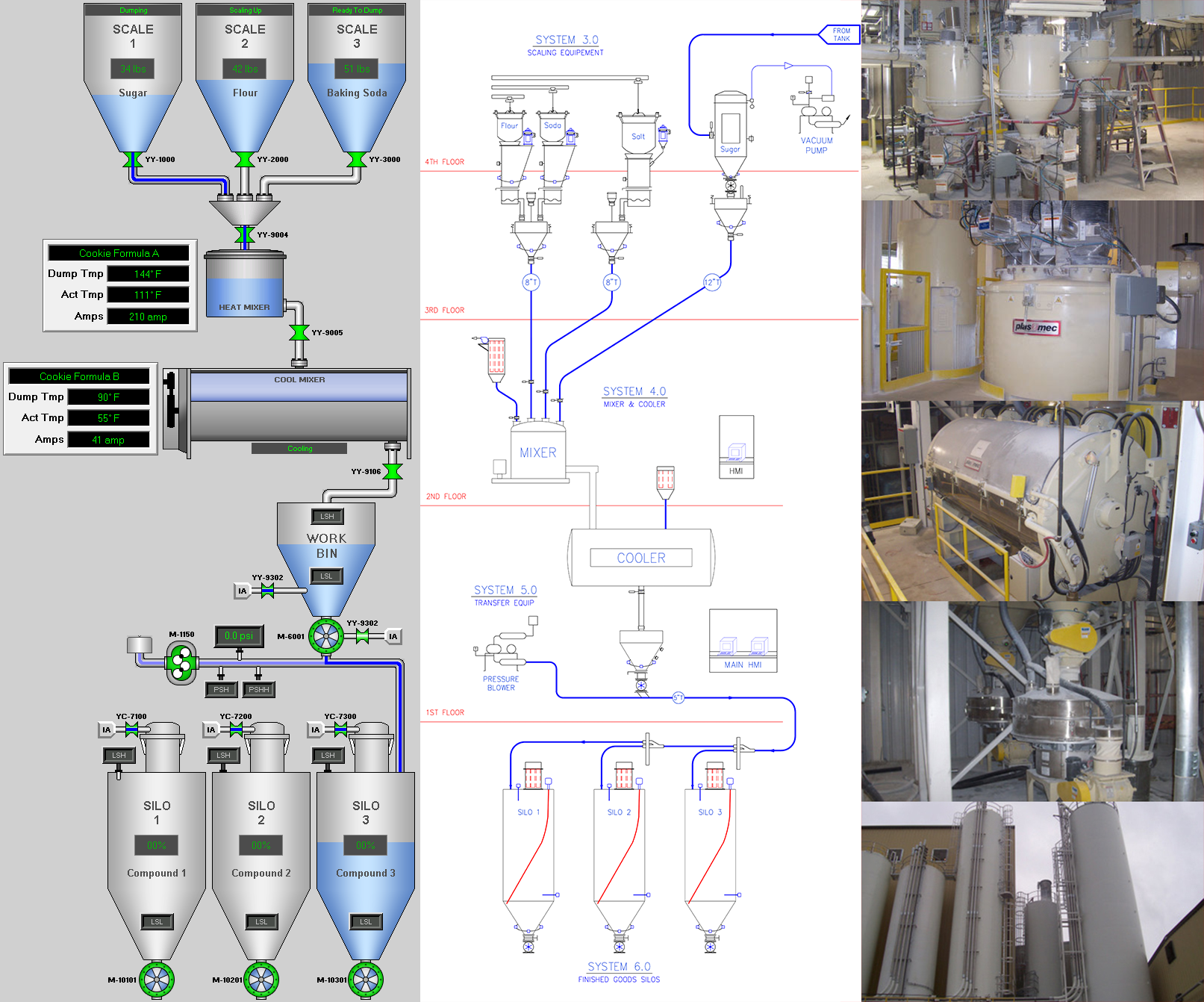

EXAMPLE OF HMI, CAD DRAWING, AND SITE

Repair

AES can help you extend the lifetime of your existing, but aged, automated equipment. We specialize in re-engineering equipment that may be mechanically reliable but electrical obsolete. Our retrofit/upgrade solutions will provide state of the art PLC and HMI controls to your legacy equipment at a fraction of the cost of new machinery. You benefit from reduced downtime, reduced maintenance, greater throughput and more advanced reporting and alarming abilities.

Replace

All projects are comprehensively engineered and documented with the end-user utmost in our minds. We provide detailed and comprehensive documentation including Upgrade Master Plans, Specifications Definitions, Functional Design Documents, Electrical Engineering, Panel Design, P&ID’s, CAD drawings, Conduit and Cable Schedules, Bid Documents, HMI development, PLC development, Factory Acceptance Tests, Startup and Commissioning, and IQ's/OQ's/PQ's protocols as well as Operator’s Manuals and documented Training.

Upgrade

Retrofits and upgrades are a necessity to remain competitive in today’s nimble manufacturing economy; let AES apply our experience to ensure that your existing automation systems are delivering the most for you today. Our Past retrofit projects have included: Allen Bradley PLC-2’s to Allen Bradley ControlLogix PLC’s, Square D Symax PLC’s to ControlLogix PLC’s, Allen Bradley 1771 IMC 120 Drive System to Ultra 3000 Drives, Allen Bradley 1771 IMC 120 Drive System to Allen Bradley, Kinetex 6000 Drives, Pacific Scientific Servo Drives to Bosch Rexroth Servo Drives, Cutler Hammer Panelmate HMI’s to Allen Bradley Panelview Plus HMI’s, Allen Bradley Panelview 1200 HMI’s to Allen Bradley Panelview Plus HMI’s, CTC HMI’s to Wonderware HMI’s, Upward migration of all Wonderware and Intellution FIX SCADA packages, DH+, DH-485 and Serial communication to Ethernet based systems, Upgrade of existing discrete field sensors to fieldbus approach such as Profibus & Devicenet.

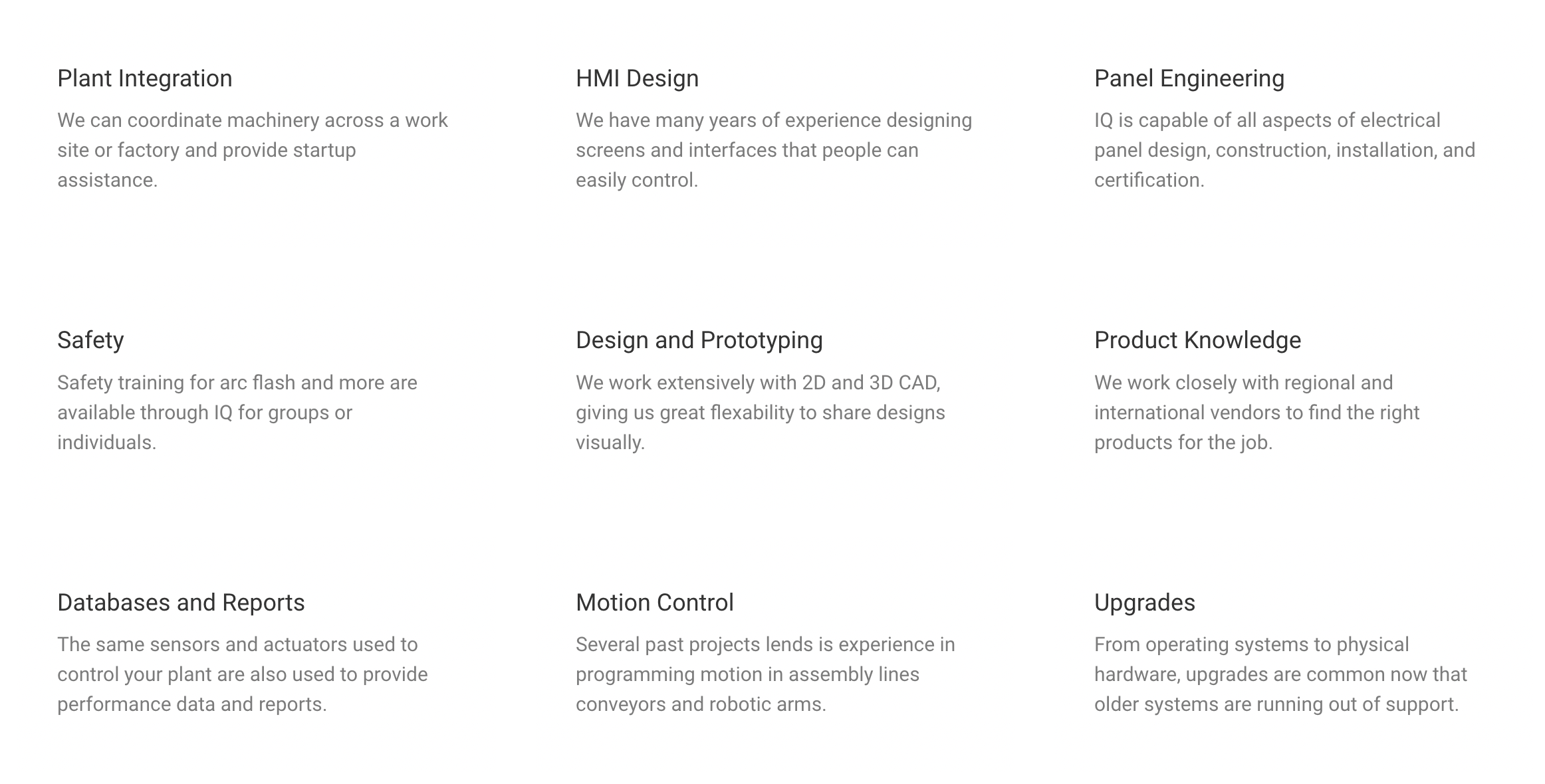

WHAT WE DO BEST

INDUSTRY APPLICATIONS

Dry Material Handling

Automated Engineered Systems (AES) is an industry leader in developing automatic full scale Dry Material Handling solutions. Partnering with General Contractors and OEM personnel, AES has successfully designed, developed, and installed our fully automatic systems nationwide. Our Projects Include: PVC Blend Towers Extrusion Delivery Systems Rail Car Unload Systems Scaling Systems (major and minor ingredient scaling) Compounding Systems Bin Management Systems Pneumatic Conveying Systems Box out systems System Upgrades from obsolete controllers to modern controllers All projects are comprehensively engineered and documented including, Electrical Engineering, Panel Design, P&ID’s, CAD drawings, Conduit and Cable Schedules, Bid Documents, HMI development, PLC development, Startup and Commissioning, Operator’s Manuals and Training. Industries we serve are: Pharmaceutical, Plastics Compounding, Wall Texture manufacturing, Floor Tile manufacturing, Ceiling Tile manufacturing, Food, and Building Products. Let us tell you about how we can help with your next system installation – or upgrade your current installation to the next level.

Machine and Motion Control

AES has been applying our automation skills to solving sophisticated Machine/Motion Control challenges since 1990. We utilize state of the art hardware including: Servo motors, VFD Drives, Encoders and Autonomous Vehicles. Whether it’s positioning 20mL vials, or 16,000 lbs of saw blades, we have done it! Our Past projects have included: Coordinated, Multi Axis motion control Precision Point to Point Positioning Control Automated Material Handling Vehicles Velocity Control Linear Positioning Line Synchronization Electronic Gearing Registration Systems Filling Lines Web Roll applications Conveyor and Sorting Systems Machine/Motion control Automation requires a specialized and experienced system integrator, let AES apply our experience to ensure that your critical Machine/Motion control application exceeds your goals. All projects are comprehensively engineered and documented with the end-user utmost in our minds. We provide detailed and comprehensive documentation including Specifications Definitions, Functional Design Documents, Electrical Engineering, Panel Design, P&ID’s, CAD drawings, Conduit and Cable Schedules, Bid Documents, HMI development, PLC development, Factory Acceptance Tests, Startup and Commissioning, and IQ's/OQ's/PQ's protocols as well as Operator’s Manuals and Documented Training.

Pharmaceutical

Automated Engineered Systems understands the strict regulations, and expectations of pharma environments. Automated Engineered Systems has been providing automation services to the pharmaceutical industry since 1999. We are experienced in applying our solutions within the framework of a quality environment where cGMP and 21CFR 11 requirements must be met. We have "classed" and "aseptic" experience and training. Automation in the pharmaceutical industry requires highly specialized system integration. Let Automated Engineered Systems apply our experience to ensure that your critical pharmaceutical automation project is completed on-time, on-budget, and most importantly, within compliance.